Where to start? I bought this machine on a complete whim, not having any experience running these machines, and with a good basic understanding of 2d design with regards to cut paths, and the like... For the last 4 years I've been building molds for longboards. Started out doing it by hand, and ended up with a modular kit of assembly mold features for longboards. Very fun stuff to design, when thinking about how the foot interacts with the surface, and how that in turn transmits force through to the trucks. I have always wanted a 3d machine. The day the opportunity came to do 1-2" mold carvings, I bit into the idea, with full intent to do it by the CW rules, or to hack the machine figuring out how to do what I want. Or maybe I'll have to just buy/build something bigger.

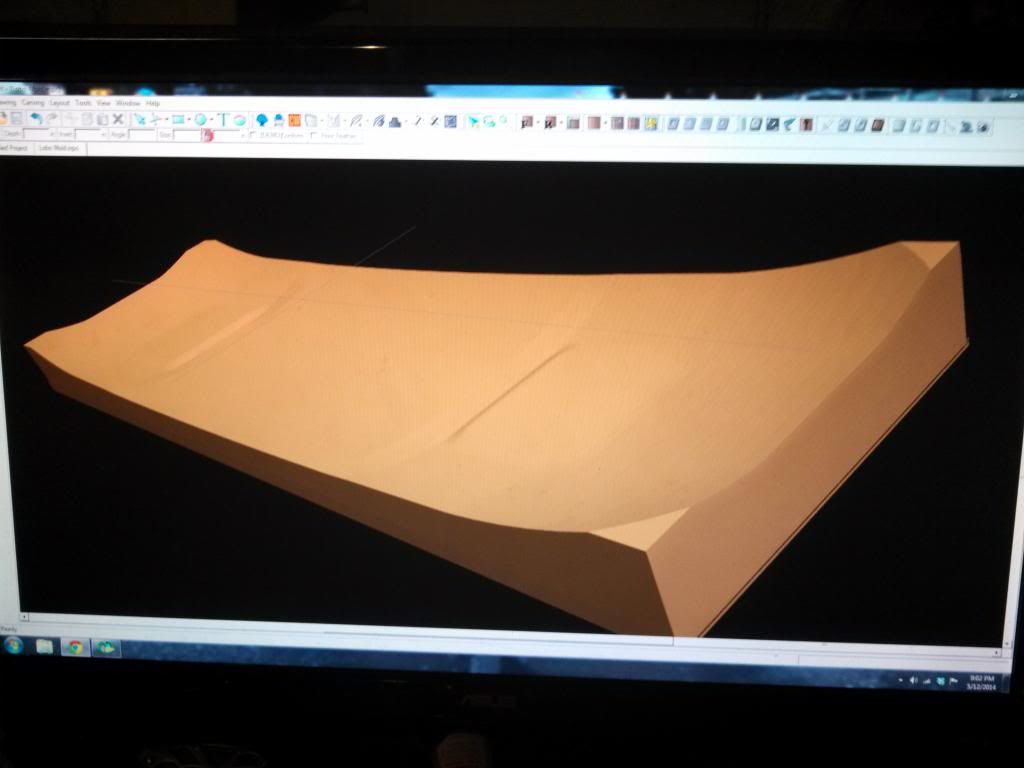

I did speak in depth with a nice lady at CW who informed me that I came in outside the circle of what this machine does. Some boxes are circular I suppose. Anyways, the machine will be used for this purpose, but my intent is to get cut times WAY down. I have many questions about substrates, and would like to know if MDF can be used with ease. I have intent to cut projects such as the ones I have uploaded/attached. These are my first few attempts at importing gray scale images from Adobe Illustrator CS6. The blend tools allow for a very interesting gradient usage, and while the precision may be lacking from a traditional 3d design software, organizing pixels in the gray scale seems easy, and doable. PS, the mold/press technique I use only requires 1 side of the mold (female). Pneumatic bladder pressing FTW.

I have a B machine, with 20 hours or less of cut time. I have purchased the most recent base software. Not sure if I should be looking at the 3d designer or maybe one of the export programs, however, I prefer doing it the hard way for now given budget. (maybe a month or so). The hard way is gray scale images, in adobe illustrator until I can do cooler stuff with it. None of these attached files have been smoothed in adobe before being imported to the software, and I believe I can make the surfaces very much more flat with just a bit of make up.

I need to purchase the 3/16" cut bit, and probably the 1/8" long bit as well, but I am not willing to break bits as often, because I will be running long files, with deep cuts. If I can get away with doing 4'x12" carve sessions, then I will.

Is there a brick headed for me?

upper kicks.mpclower double kick.mpcST1 blend expirement.mpcST1 x 40.mpc34 in all her glory.mpcupper kicks.mpclower double kick.mpc34 in all her glory.mpcST1 blend expirement.mpcST1 x 40.mpc

Reply With Quote

Reply With Quote