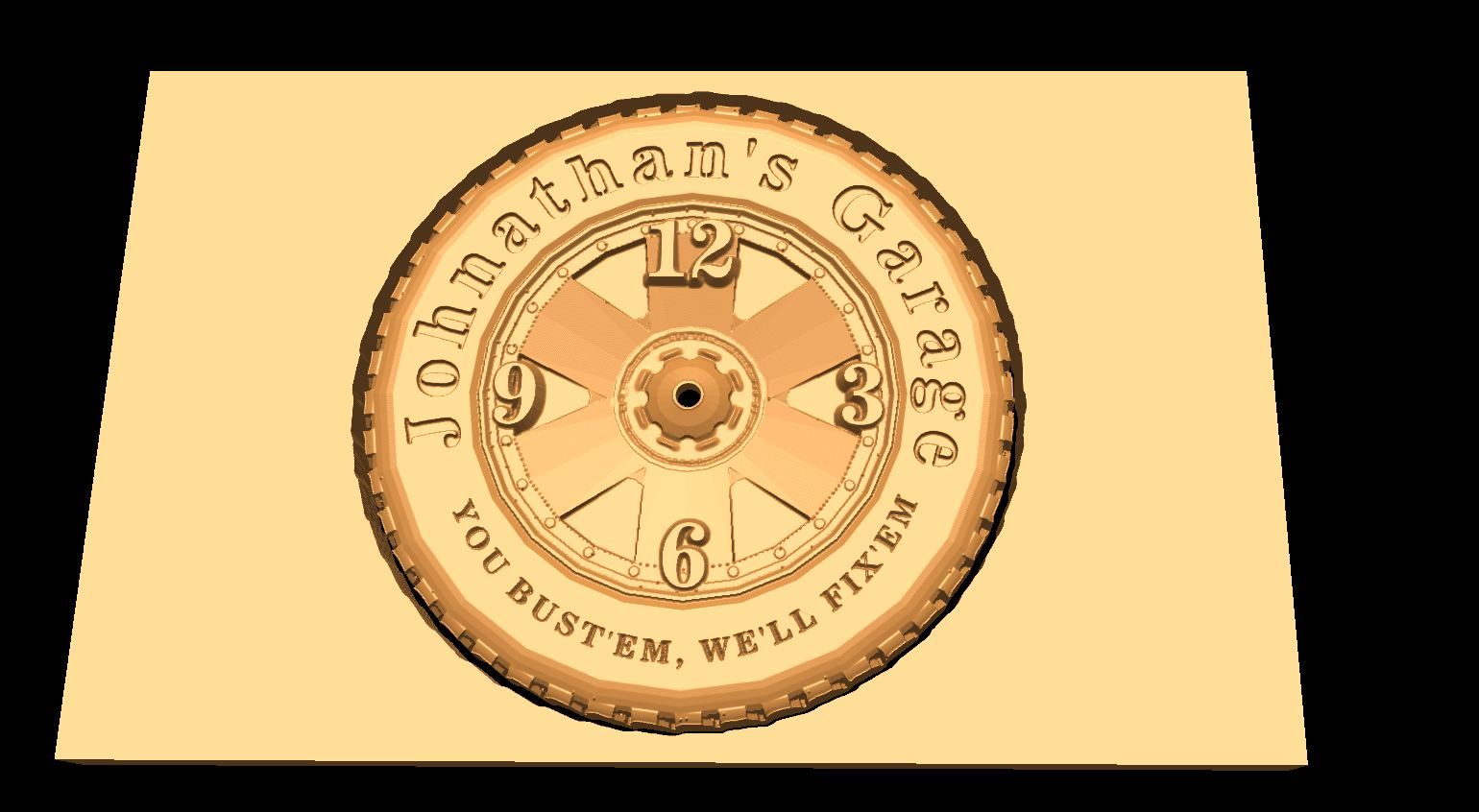

Here's a clock I just made for a member of another forum- This was fun to carve and finish

For the carving I used some very dry douglas fir (from a 2 x 8 I ripped the pieces to 6 1/8 to fit on my jointer, face jointed and planed down to just over 1 inch thick, then glued up the 2 6 1/8 pieces. I then planed the glueup down to exactly 1 inch and had a VERY straight 12x1 board with VERY tight grain.

This is a great example that you can successfully use softwoods like DF in your cw, but it really does need to be very dry and prepared properly to carve nicely. I have not had tons of luck in the past with conifers, but this wood is so dense that it almost carved like a hardwood (dense but DRY) and required zero sanding (approx 2 hour carve on best)

I then used white paint for the letters and onyx stain (so the grain would show) and silver/gold rub-n-buff for the accents.

I'm really happy with the way this turned out... now just 3 more (different) clocks to make this weekend...

Lawrence

Reply With Quote

Reply With Quote