Last edited by fwharris; 07-21-2013 at 02:10 PM.

RingNeckBlues

My patterns on the Depot

DC-INSERT It Just Sucks!

Proven to out perform all others!

Buy CarveWright

Colorado FaceBook Users Group

All patterns and projects that I share on the CarveWright forum are for your personal carving purpose. They are not to be shared, sold or posted on any other web site without permission from RingNeckBlues Designs.

Well took a break last night, but back add it now.

I ran 120ac to the cut motor and nothing. Just quiet. I varified with a meter that the power was on the cut motor input leads.

I opened up my old A model and ran 120ac to the cut motor. It spun beautifully.

So I think my cut motor is gone. I double checked my hours and I have 43H 33Min on the machine.

Is thier something else I should do, or just phone LHR. Also do I have to wait till they fix mine and send it back, or do we just mail each other a cut motor?

Lastly.......I do not want to void any warranty. Do I move my cut motor over from my A model?

Carvewright A machine 2007

Carvewright C machine 2013 DC-Insert

Mavric iMac i7 16gig latest version

Designer 1.187, Designer 2.04, Centerline Text, Conforming Vectors, STL importer, DFX importer, Pattern Editor and probe

With so few hours on the motor, I would guess a clip or a wire is off inside. You could switch motors and send the bad one in.

I would take it apart and maybe be able to fix it. There are little clips which can come off the brush holders which would be an easy fix.

If your machine is under warranty, You should contact LHR about it. Most likely they will ship you another motor AFTER they run through the troubleshooting and testing procedures and determine this is the problem. This is a requirement for them to document everything with the problem.

The speed of the cut motor is sped up for doing centerline, so that it doesn't burn the wood. If for some reason it cannot reach that speed, it will give you the "check cut motor" message. (May be an issue with the cut motor not going fast enough or a dull bit slowing it down.) If you say continue, it won't give you the message again, until the machine has been turned off and then back on.

CarveWright CX Packaged System - starting at $2000

CarversClub 1 Year Subscription - $150.00/year

Adv. Support w/out CC membership - $25.00/issue

CarveWright Community Forum - PRICELESS!

Thanks Connie. This happened over the weekend so I did some testing of my own. I am a Computer Engineer (hardware) so I have a fully equipped shop.

I tested the input power to the cut motor and it was thier, but the motor is silent. It justed stopped durange a carve. It gives no errors and caries on the carve but does not spin. Doing the 0,8 Cut Motor test, it says its running but it is not. I installed my cut motor from my A model into my new C model and everything works fine.

On the bench I applied 120ac to the cut motor and nothing happens.

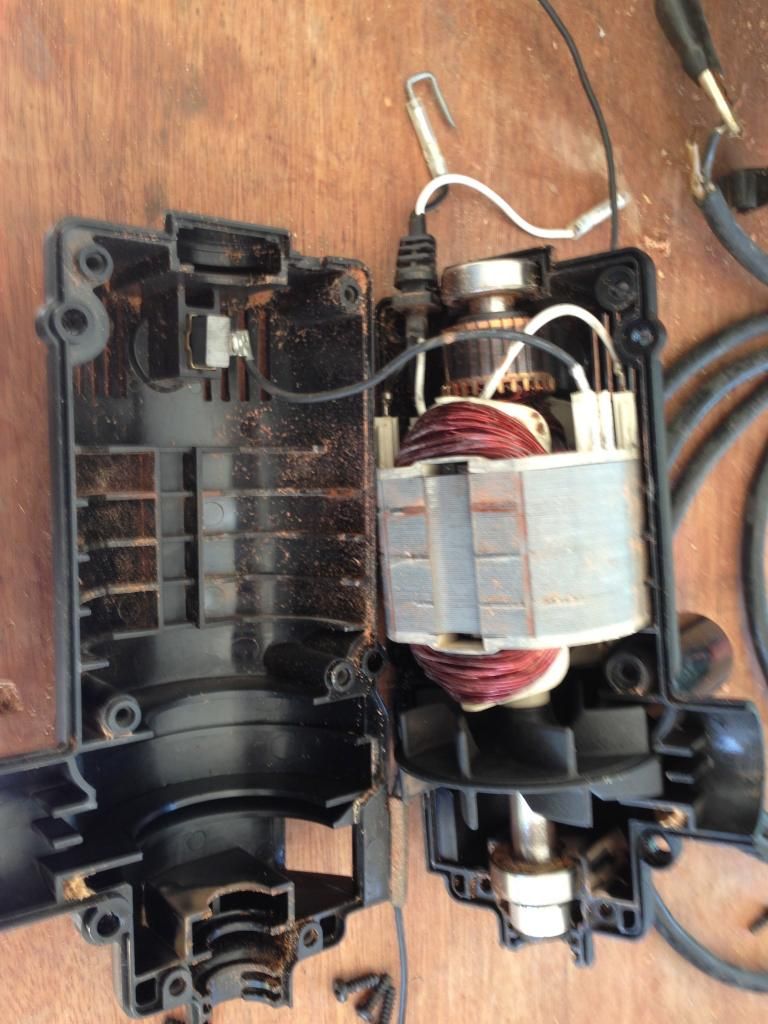

I opened it up here, but everything seems fine.

I think I would like to change it unless someone knows what it might be.

Carvewright A machine 2007

Carvewright C machine 2013 DC-Insert

Mavric iMac i7 16gig latest version

Designer 1.187, Designer 2.04, Centerline Text, Conforming Vectors, STL importer, DFX importer, Pattern Editor and probe

There must be a physical broken connection somewhere between the brushes and the field. (Those little wires on the brushes themselves?)

Have you tried applying line voltage to the motor out of the machine?

Check continuity of the connections and windings?

I can't remember if this motor has a thermal fuse...

Last edited by brdad; 07-22-2013 at 03:26 PM.

Yes, tested on bench with 120vac applied. Nothing, no sound. It was dust on the wire. Checked that 120ac was getting to the internal clips. Have not gone further. Not willing to remove the other one and compare readings. My guess is that the coil must be open. A short would only reduce the power of the motor.

Carvewright A machine 2007

Carvewright C machine 2013 DC-Insert

Mavric iMac i7 16gig latest version

Designer 1.187, Designer 2.04, Centerline Text, Conforming Vectors, STL importer, DFX importer, Pattern Editor and probe