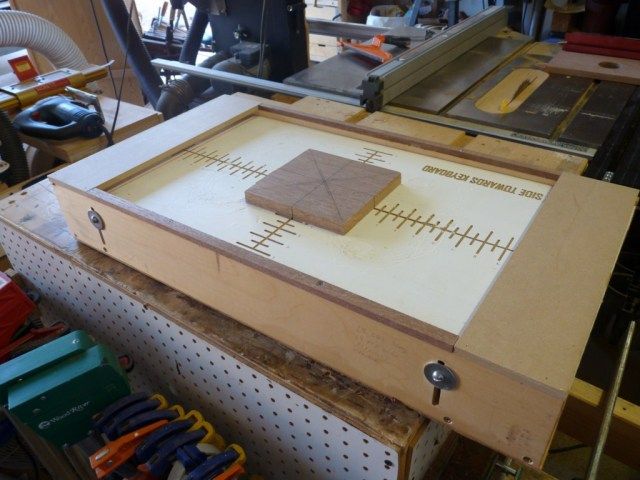

After quite a bit of reading and comments lately on the subject of sleds, I thought I'd show y'all mine. I've made some recent improvements. A couple of you will be happy to hear that my sled requires no masking tape for the sensors now! I know I've been promising I'd post pics about this for a while now but I wanted to get my improvements done before I showed it. I do plan to make another that is less "robust" as I over-engineered this one a bit. With the new "four-inch" stretchers on the ends, I shoudn't have to worry about racking and could make the whole assembly much lighter without comprimising strength.

The sled is basically a long "U" shape that has an inner "floor" that can be raised and lowered to accommodate different thicknesses of materials. The "floor" rides on 4 bolts which can all be loosened and then tightened to the correct material thickness. To do so, I loosen all four and then hold the material up to each corner and tighten the bolt appropriately.

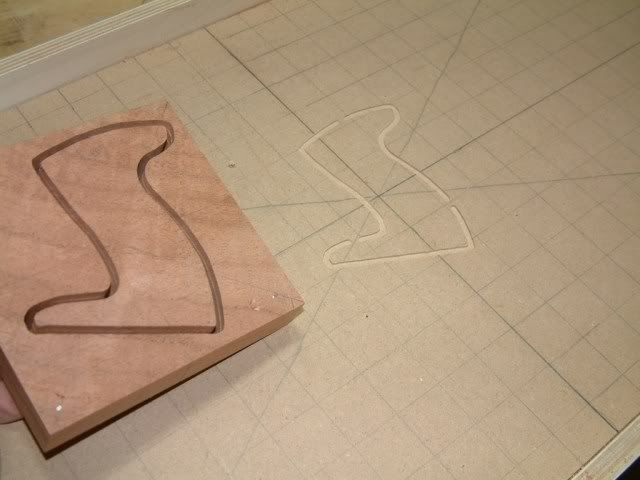

This pic shows the grooves for the bolts.

This shows the inside- the lower "square" holds the nut that the carriage bolt tightens into. I'll use threaded taps on my next version but I will say that the extra thickness does keep the piece from racking too much.

To use the sled I put the piece to be carved into the center with double stick tape (It hasn't failed me yet... very tough stuff as I use the kind woodturners use) I carved marks showing the center of the sled with my CW-- this makes lining up the piece in the center very easy. I then put the sled all the way to the right with the left side "four-inch rail" under the sensor. I then just use the sled as normal, ensuring I use "center" for everything. Perhaps there is a better way to do all this, but it works for me and there is no loss of material.

Let me know if you have questions,

Lawrence

Reply With Quote

Reply With Quote