Al.

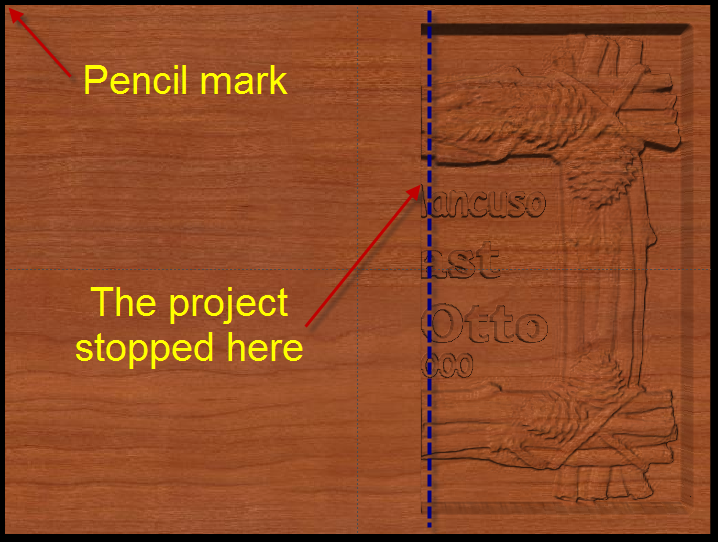

Again, we don't know what they need or what is used as the offset to store from, just checked my card and orig file was 1791K and space available was 3496K. Seems like that should be enough space but then again, a programming issue probably isn't only about memory available.

Again, thx for the feedback, as we know, multiple perspectives help.

Rick H.

Reply With Quote

Reply With Quote